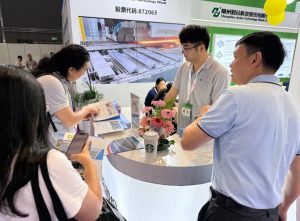

Junhe Technology at SNEC PV+ International Solar Photovoltaic Conference — Exhibition Highlights

On June 13th, the three-day Shanghai Photovoltaic Expo concluded. As a key player in the industry, Junhe Technology showcased its technical strength and innovative achievements, attracting widespread attention. The expo not only provided Junhe with a platform to engage and collaborate with global customers but also offered clearer insights into the development trends of the photovoltaic industry.

Innovation-Driven Development Strategy

Facing industry challenges, Junhe Technology consistently adheres to an innovation-driven development approach, committed to enhancing the company’s core competitiveness. At this exhibition, Junhe showcased a series of innovative products and solutions covering the entire industry chain, including wafers, cells, modules, and mounting structures, attracting significant attention from both domestic and international clients.

In the wafer cleaning segment, Junhe upgraded its cleaning agents to improve product adaptability and combined them with tailored client service solutions, providing a more optimized product model. The new generation of diamond abrasive wire cutting fluid maintains a low wire breakage rate and stable yield, adapting to various processes.

At the cell level, Junhe focuses on overcoming technical challenges of TOPCon and PERC cells. The introduced texturing additives enable low weight loss, strong cleaning ability, and consistent texture at relatively low process temperatures. The alkaline polishing additives significantly reduce alkaline replenishment with a wide application window. The amorphous silicon additives for cells greatly reduce chemical usage, addressing the technical difficulty of leakage current in TOPCon cells.

In the module segment, Junhe has developed environmentally friendly flux agents that perfectly combine ease of application in soldering and long-term reliability. The anti-reflective coating liquid for photovoltaic glass achieves maximum transmittance enhancement while ensuring aging resistance and dirt repellency. The zinc-aluminum micro-coating for photovoltaic mounting structures complies with RoHS standards, improves coating hardness, and significantly enhances salt spray resistance beyond 1600 hours, solving issues related to primer acid resistance, alkali resistance, and impact resistance.

Additionally, Junhe has increased investment in R&D, continuously driving technological innovation and product upgrades. This has established a strong brand reputation within the industry, with product quality consistently ranking among the top tier and obtaining quality exemption certifications from multiple strategic customers.

Expand overseas markets and implement a global strategy

While consolidating its domestic market, Junhe Technology is actively expanding into overseas markets and implementing a global strategy to bring its products and services to the international stage. At present, Junhe’s products have been exported to many countries and regions including Europe, Southeast Asia, and the Middle East, earning recognition and trust from international customers.

Work together to create a green energy future

In the face of both challenges and opportunities in the photovoltaic industry, Junhe Technology will continue to adhere to its innovation-driven development strategy, continuously improve its technological capabilities and product quality, and expand into overseas markets to provide customers with better products and services.

Let us work together to promote the development of the global photovoltaic industry and strive for a future of green energy!